HEAT TREATMENT

Welding Preheat Treatment

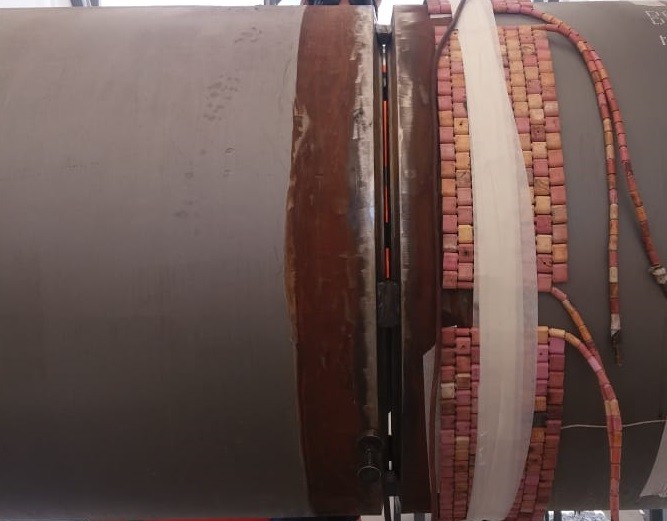

Preheating in welding is a critical process that minimizes temperature differentials between the welding arc and the base material. By reducing shrinkage stresses, preheating helps prevent cracking and distortion in the weldment. It also slows the cooling rate of the finished weld, resulting in a less brittle and more ductile weld with reduced hardness in the heat-affected zone (HAZ). Additionally, preheating assists in hydrogen escape from the weld puddle, reducing the risk of cracking. Our preheat treatment services ensure optimal welding conditions, particularly for highly restrained weld joints and materials prone to brittleness. Trust TechCorr to optimize your welding processes for superior integrity and durability.