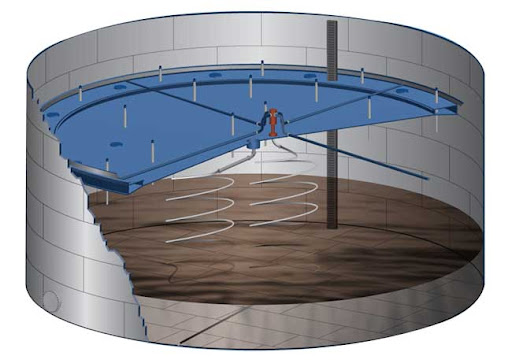

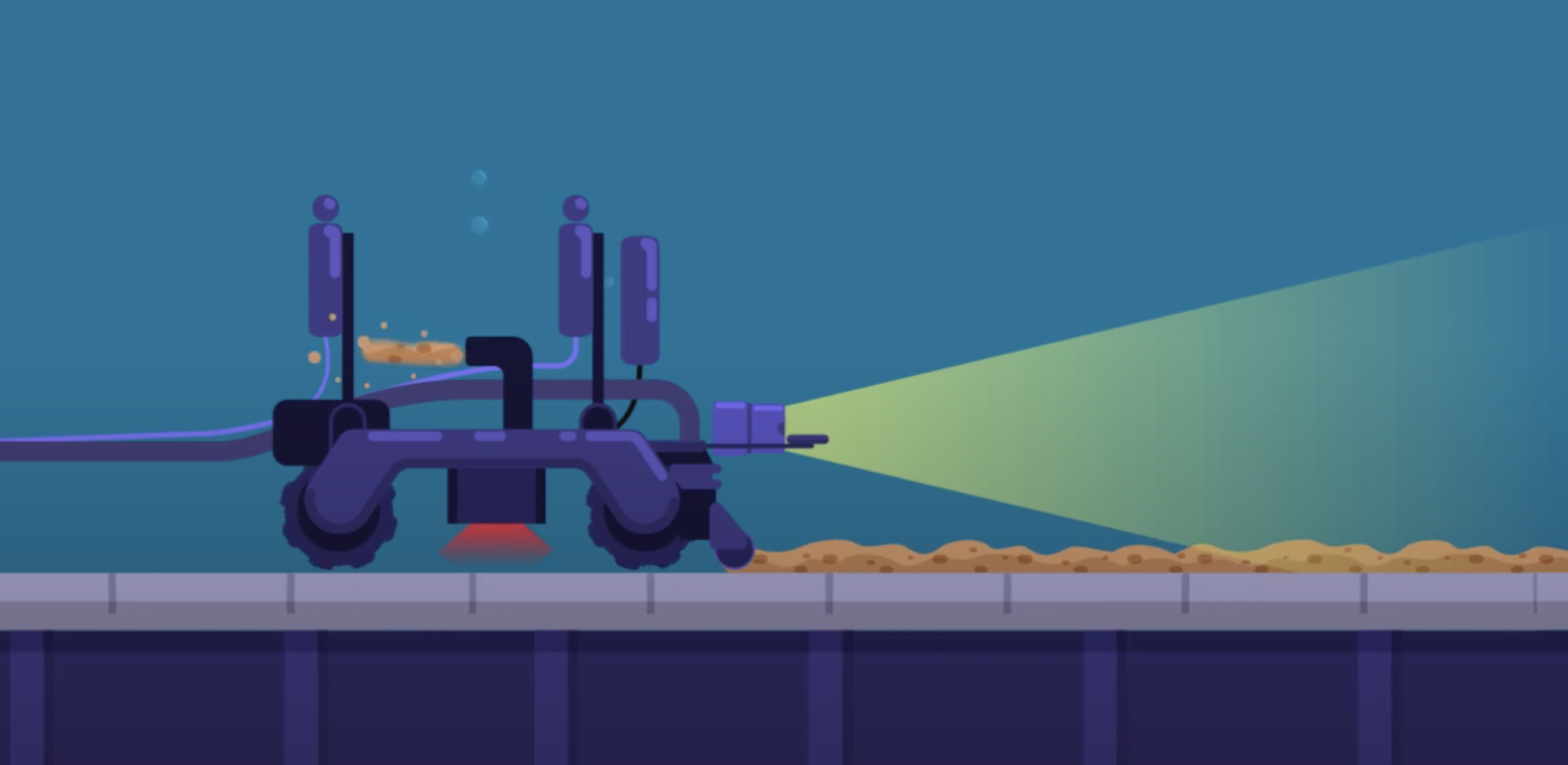

The inspection process begins with the deployment of our intrinsically-safe (IS) scanners, designed to inspect tank bottoms without the need for tank removal or personnel entry. These high-density ultrasound scanners are capable of operating in both fixed and floating roof storage tanks, even when the tank is full of product. We offer a range of robotic equipment deployment options, from manually maneuvered scanners to multi-sensor remotely operated robots, ensuring versatility and adaptability to different tank configurations.

Our inspection process also includes video inspection where optically clear, allowing for detailed visual analysis of tank conditions. Precision navigation systems ensure accurate positioning and movement within the tank, while API 653 certified inspectors oversee the entire inspection process to ensure compliance with industry standards.

In addition to ultrasound scanning, we offer 3D LIDAR laser scan tank analysis, providing comprehensive assessments of settlement, outer roundness, plumbness, berm capacity, and more. This advanced technology enhances the accuracy and reliability of our inspections, enabling us to identify potential issues with precision.

Our reporting system includes on-site preliminary result reporting for immediate feedback and rapid final report turnaround for comprehensive analysis. All reports are API 653 compliant, ensuring consistency and reliability in our inspection processes.

TechCorr's Ultrasonic Tank Floor Robot is ideal for situations where in-service inspections are necessary, such as when unknown conditions exist, integrity recertification is required, or for new and older tanks with known degradation. By combining cutting-edge technology with expert personnel, TechCorr delivers API 653-compliant inspections of above-ground storage tanks without the risk, cost, or hassle of removing tanks from service.