Optimize Project Timelines & Minimize Operational Disruptions

Ultrasonic P-Scan Technology, employed by TechCorr, epitomizes cutting-edge precision in non-destructive testing (NDT). This innovative technology operates seamlessly in automated raster scanning or semi-automated manual manipulation modes, offering versatility in inspection methodologies.

By leveraging multiple angle beam transducers operating independently, P-Scan ensures meticulous defect localization and sizing with unparalleled accuracy. Its application extends across various industries, primarily focusing on the meticulous assessment of operational asset health and the facilitation of rigorous Fitness-for-Service evaluations. P-Scan's ability to generate precise damage mechanism results renders it indispensable in the quest for optimal asset integrity management, enabling engineers and plant operations managers to make informed decisions with confidence and efficiency.

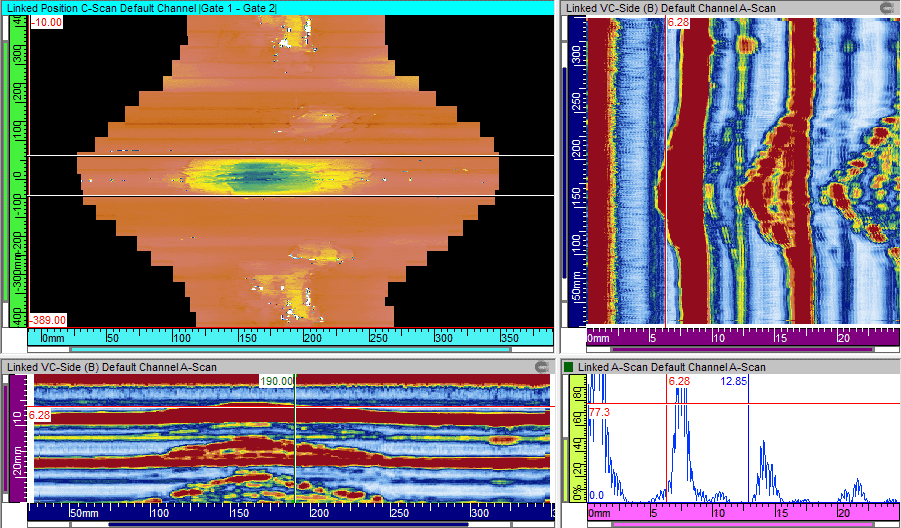

The P-scan system provides A-scan, B-scan, T-scan (thickness measurement) and ToFD (Time of Flight Diffraction) mode including averaging for sizing of defects. Furthermore, the system provides projection images of the object under examination, e.g. images of the weld or part of an object. In the three projection images, called TOP,SIDE and END views, the flaws which have been detected are automatically shown at their correct location. P-scan is named because the processed data are depicted in so called Projection View Images and the system is then called P-scan in short for Projection-view-Scan. P-scan for weld inspection;T-scan for corrosion mapping; ToFD for detection and sizing; Full A-scan recording for off-line processing.