Short Range Ultrasonic Testing of Critical Zone One In Aboveground Storage Tanks

Above Ground Storage Tank (AGST) bottom consists of two separate sections, the central portion (referred to as bottom plate) and also a Sketch Plate or an Annular Plate. The bottom plate is like a membrane that is continously supported by the foundation and there is no stress on it. The sketch plate or annular plate forms the perimeter of the tank and supports the tank shell.

The critical zone of tank bottom is the area upto 3 inches of inside edge of the shell, measured radially inward on the sketch plate or annular plate. This section of the annular plate is supported by concrete ring wall or crushed stone and it might be in highly stressed condition. Because of this reason identification of internal and external corrosion are of great importance to maintain structural integrity of the entire tank. Chances of severe corrosion to occur in the critical zone is high because of seepage of raainwater through edges of the annular plate. This may be due to edge settlement or cracks in the basement or inefficiency of Cathodic pretection system in this region. This is of major concern because inspection in this region is practically not possible with conventional NDT methods. Other advanced floor scan techniques can never reach near to fillet weld from inside during out of service inspections.

In the current case study, an attempt was made to assess the corrosion in the critical area. Further damage to the structure can be prevented by identifying the active corrosion areas before they lead to a leakge. As stated above, with the available conventional ultrasonic techniques it is difficult to scan and represent the damaged areas because of geometrical factors involved.

Short Range Ultrasonic Testing (SRUT) using array technology is a great application method to resolve this concern. With the current technology it is possible to inspect upto 4 inches of inside edge of shell from the external annular plate extension when the tank is in-service condition. Some of the features of this technology are as follows:

- In-Service inspection of criticial areas. No need to take out the tank for an outage.

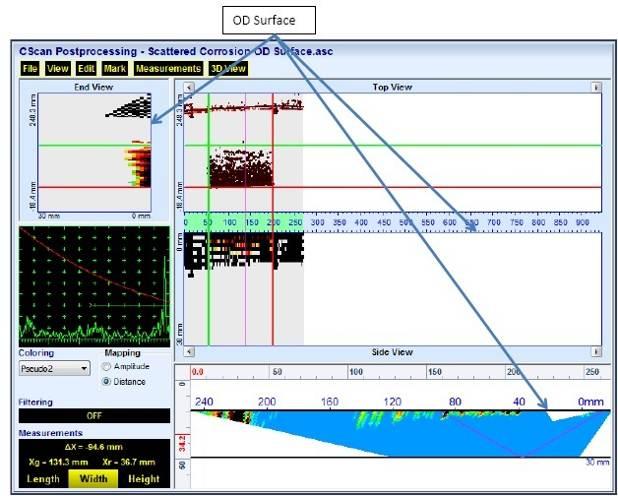

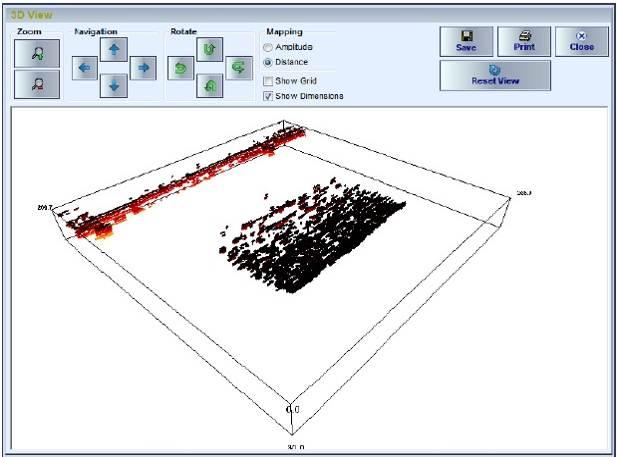

- True- To – geomety/ Annular Ring overlay volume corrected imaging with sectional side/ end view and planar top view to accurately locate the corrosion and distinguish its presence on top or bottom side.

- Depth detection and accurate sizing.

- Built-In Fillet Weld / Annular RIng Geometry Editor and Ray Tracer functions in the software makes interpretaion easy by eliminating complexity of signals coming from weld toe regions through interpolation. Equally sensitive to top side & bottom side corrosion along with pitting & general corrosion.

Scan results showing topside pitting in the critical zone of tank bottom