Optimize Project Timelines & Minimize Operational Disruptions

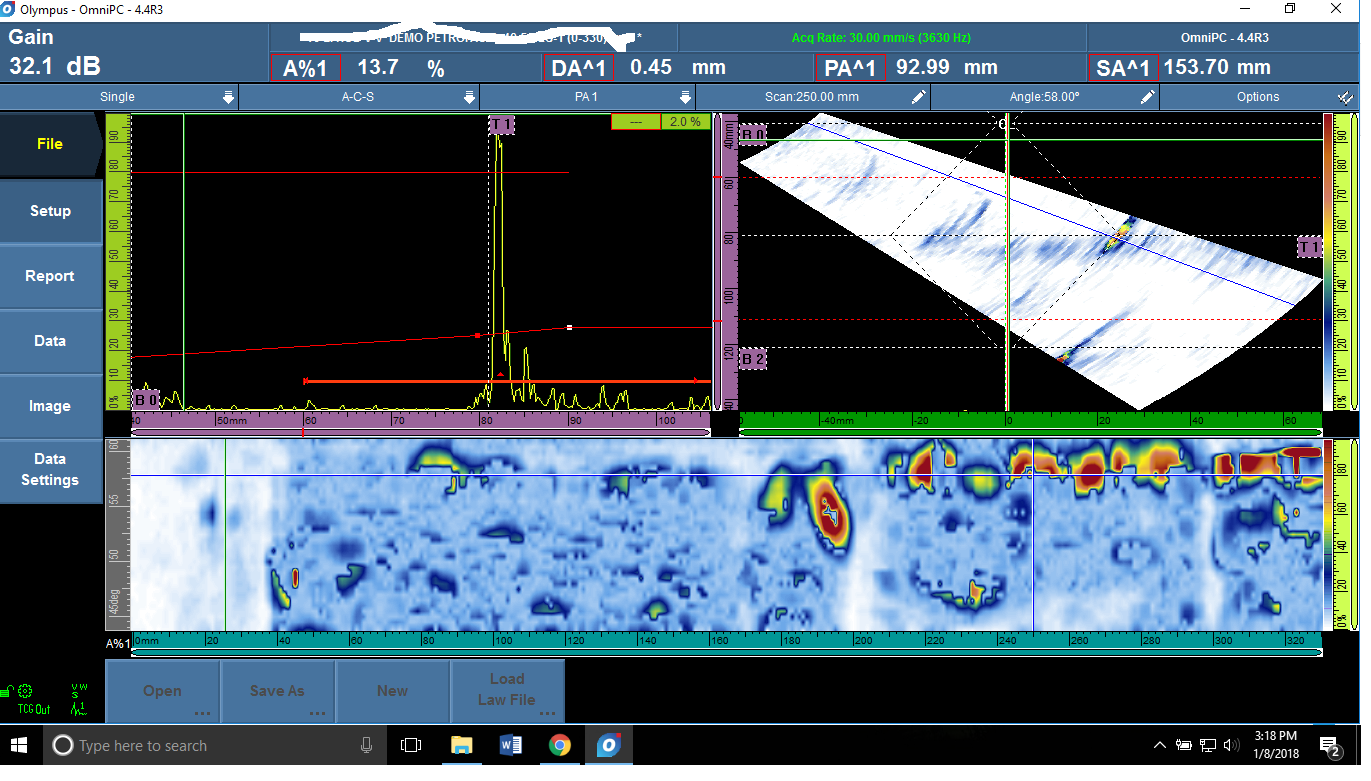

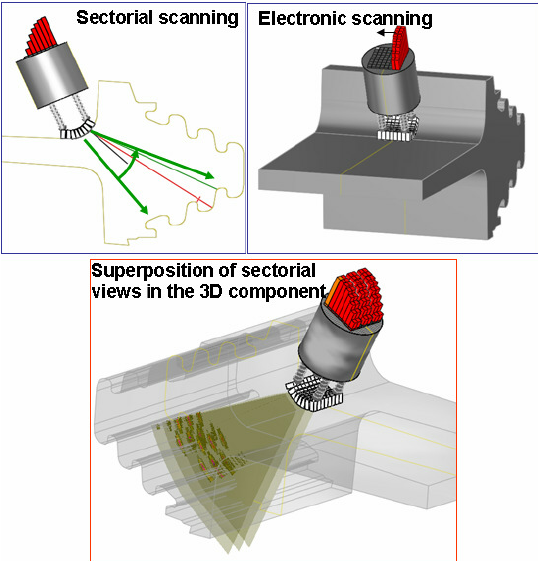

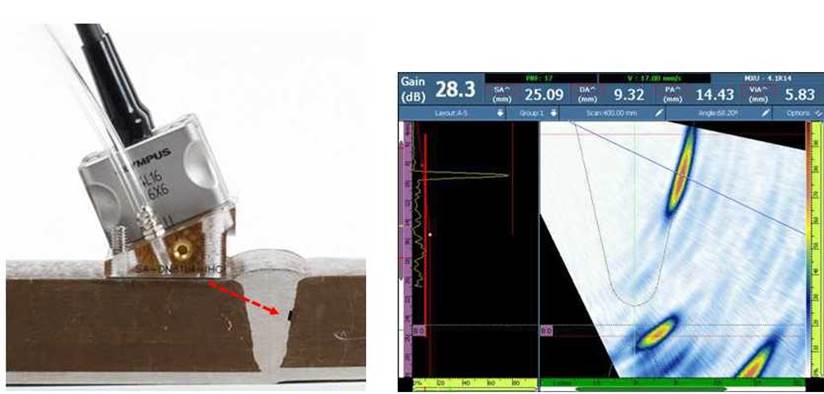

Phased Array Ultrasonic Testing (PAUT) represents a paradigm shift in non-destructive testing, offering unparalleled versatility and efficiency. At TechCorr, our Ultraview™ solution harnesses the power of PAUT to deliver real-time sectorial scans (S-Scans) that provide comprehensive volumetric examinations from a single inspection point. Unlike conventional methods, PAUT equipment can detect defects irrespective of their orientation to the transducer, enabling thorough inspection of welds, accurate thickness measurements, corrosion detection, and precise crack identification.

Ultraview™ integrates specific training protocols, internal qualification standards, specialized equipment kits, calibration standards, and examination procedures to ensure the systematic and disciplined approach mandated by industry codes. By leveraging PAUT technology, TechCorr empowers engineers and plant operations managers to optimize inspection processes, mitigate safety hazards, and enhance productivity across a wide range of applications.