PIPELINE NDE

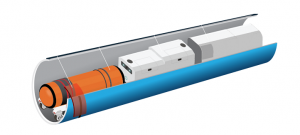

Mainline Pipeline Construction X-Ray Crawlers

TechCorr harnesses the power of 3D reality capture solutions and advanced laser scanning technology to revolutionize surveying practices. Utilizing sub-millimeter profiling techniques, our scanners deliver unparalleled accuracy, significantly reducing the time required for calculations compared to manual surveys