Our adept technicians employ both Dry Powder and Wet Fluorescent methods, meticulously scrutinizing components for cracks, weld inconsistencies, and stress corrosion, thereby mitigating risks and enhancing asset longevity. Whether in the field or laboratory settings, MPI remains a cornerstone of our commitment to excellence in NDT, delivering unparalleled insights into material condition and bolstering the resilience of industrial infrastructure. MPI is fast and relatively easy to apply, and surface preparation is not as critical as it is for other NDT methods. These characteristics make MPI one of the most widely utilized nondestructive testing methods.

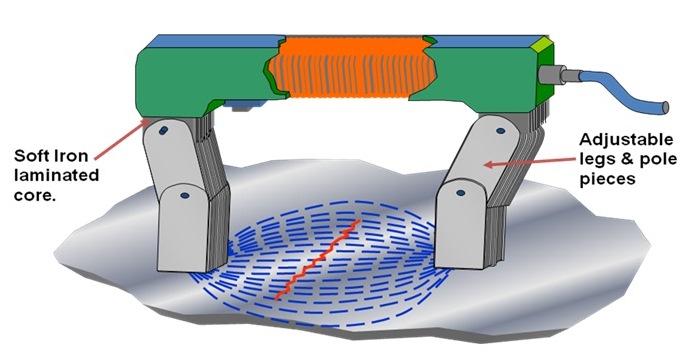

MPI uses magnetic fields and small magnetic particles similar to iron filings to detect flaws in components. The only real limitation is that the component being inspected must be made of a ferromagnetic material such as iron, nickel, cobalt, or one of their alloys. The method is used to inspect a variety of product forms including castings, forgings, and weldments. The structural steel, automotive, petrochemical, power generation, and aerospace industries are a few examples that utilize magnetic particle inspection. Underwater inspection is another area where magnetic particle inspection may be used to test items such as offshore structures and underwater pipelines.