EXCHANGER INSPECTION

Internal Rotary Inspection Service (IRIS)

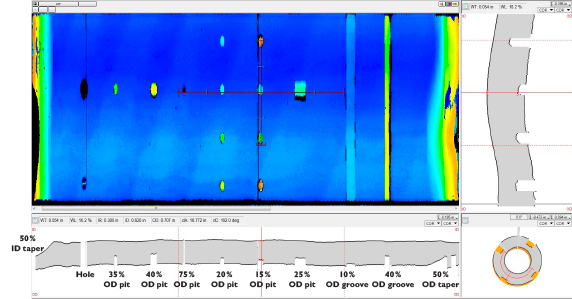

TechCorr's Internal Rotary Inspection Service (IRIS) offers unparalleled precision in ultrasonic inspection. Using a water-driven rotating mirror to direct ultrasonic beams, IRIS delivers accurate wall thickness readings and detects corrosion, pitting, erosion, and baffle wear in heat exchanger tubes. With quantifiable data presented in C-Scan and B-Scan profiles, IRIS ensures thorough assessment and reliable results for asset integrity management.