CONVENTIONAL NDE

Hardness Testing

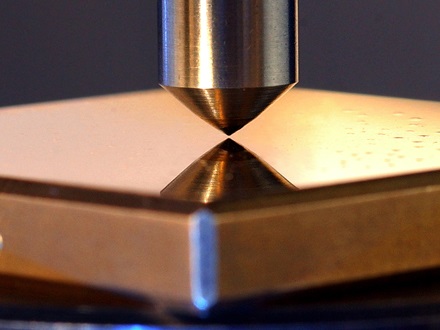

TechCorr offers comprehensive hardness testing services, providing accurate evaluations of component materials to assess their resistance to deformation. Our dedicated team of technicians conducts various hardness tests, including Rockwell, Brinell, Vickers, Equotip, and Microdur, in-house. These tests offer valuable insights into material performance and structural integrity, guiding quality control measures and component acceptance. With our expertise in hardness testing, we help ensure the longevity and reliability of your assets.