CONVENTIONAL NDE

Eddy Current (EC) Testing

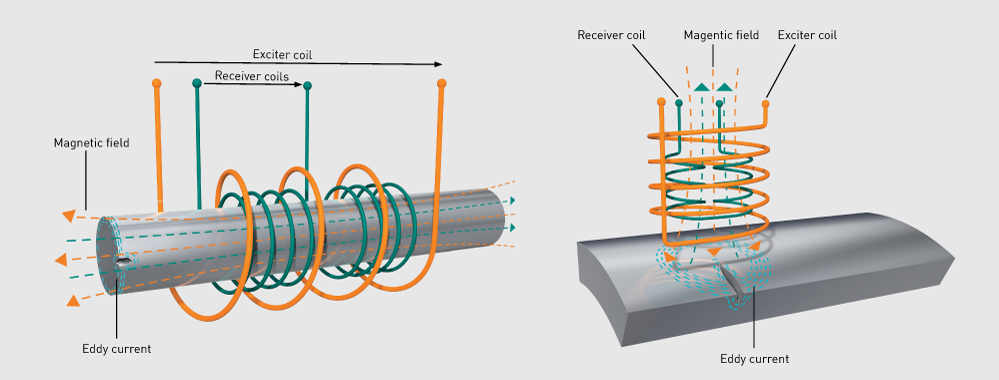

Eddy current (EC) testing, a cornerstone of non-destructive testing (NDT), utilizes induced electrical currents to assess the integrity of conductive materials. By detecting variations in current flow caused by material changes or anomalies like corrosion, cracking, or erosion, EC testing unveils potential defects, even those beneath the surface. Its sensitivity to small flaws and ability to inspect non-magnetic alloys make it an indispensable tool for asset integrity assessment.