CONVENTIONAL NDE

Dye Penetrant Testing (PT)

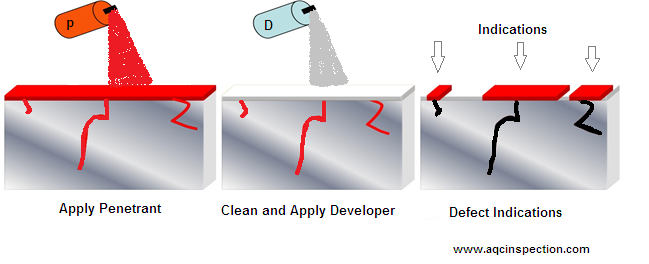

TechCorr's Penetrant Testing (PT) inspection services efficiently identify surface-breaking discontinuities on smooth, nonporous surfaces, ensuring the integrity of your assets. Our trained inspectors utilize the principles of capillary action to detect flaws accurately and reliably, providing comprehensive testing solutions for a variety of industries. TechCorr’s Penetrant Testing (PT) inspection services find surface-breaking discontinuities on relatively smooth, nonporous surfaces.