Find our latest news updates

- 713-524-2768

- [email protected]

- 1485 East Sam Houston Pkwy S, Pasadena, TX 77503, USA

FORTIFIED ASSET PROTECTION METHODOLOGY

With our expertise, comprehensive solutions, and commitment to excellence, we are your trusted partner for all your pipeline integrity needs

Our Solutions

As a leading authority in non-destructive testing (NDT) inspection, TechCorr offers an extensive range of traditional NDT solutions to meet your asset protection needs. Our commitment to innovation and expertise ensures that your assets are inspected with precision and efficiency, minimizing downtime and maximizing productivity.

Asset Lifecycle Specialist

Conventional & Advanced NDT

Improved Quality and Higher Safety

Mechanical Crafts Support

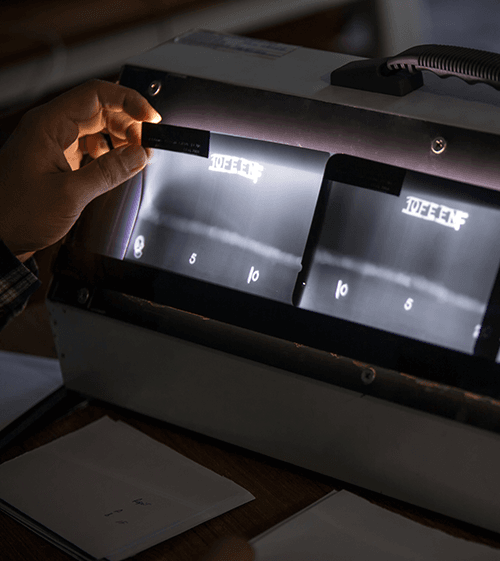

Radiographic Testing (RT)

Radiographic Testing utilizes high-energy radiation to penetrate materials and produce detailed images of internal structures. This method effectively identifies cracks, voids, and other flaws, ensuring the integrity of welds and components while adhering to industry safety standards.

Shear Wave Testing

Shear Wave Testing, a form of ultrasonic testing, is essential for assessing weld integrity and detecting defects in materials. This method provides accurate depth and size measurements of flaws, enhancing the reliability of critical components in various industries.

Magnetic Particle Testing (MT)

Magnetic Particle Testing is an effective method for identifying surface and near-surface defects in ferromagnetic materials. By applying magnetic fields and fine iron particles, this technique highlights flaws such as cracks and inclusions, ensuring the safety and reliability of your assets.

Dye Penetrant Testing (PT)

Dye Penetrant Testing is a widely used method for detecting surface-breaking defects in non-porous materials. By applying a fluorescent dye, this technique reveals cracks and imperfections, ensuring thorough inspections and maintaining the integrity of critical components.

Ultrasonic Thickness Testing (UTT)

Ultrasonic Thickness Testing measures the thickness of materials to detect corrosion and erosion. This non-destructive method provides precise readings, helping you monitor asset health and prevent failures by ensuring that components meet required thickness specifications.

Hardness Testing

Hardness Testing evaluates the resistance of materials to deformation and wear. This essential method helps determine material properties, ensuring compliance with specifications and enhancing overall asset performance and longevity.

Positive Material Identification (PMI)

Positive Material Identification ensures that materials meet specified compositions and standards. By analyzing the elemental makeup of metals and alloys, this method prevents costly errors and ensures the integrity of components in critical applications.

Eddy Current Testing (EC)

Eddy Current Testing is a versatile method for detecting surface and near-surface defects in conductive materials. By inducing eddy currents, this technique quickly identifies cracks, corrosion, and material inconsistencies, providing real-time insights into asset integrity.

Visual Testing Inspection (VT)

Visual Testing Inspection is the first line of defense in asset management, allowing for quick evaluations of components and structures. Our trained inspectors utilize established guidelines to identify potential issues early, ensuring safety and compliance while facilitating proactive maintenance strategies.

Leader in NDT and Asset Integrity Management

Why Choose TechCorr for Conventional NDE

As experts in Conventional Non-Destructive Evaluation (NDE), TechCorr delivers reliable inspection services using proven techniques such as ultrasonic, radiographic, and magnetic particle testing. Our skilled technicians provide accurate results that help you maintain asset integrity and ensure regulatory compliance, all while optimizing your maintenance strategies.

Industry-Leading Expertise

With decades of experience and a team of highly skilled technicians, TechCorr brings unmatched expertise to every NDT project. We stay at the forefront of technological advancements and industry best practices to provide our clients with the highest level of service.

Comprehensive Service Range

From traditional NDT techniques like ultrasonic testing (UT) and radiographic testing (RT) to specialized methods such as acoustic emission (AE) and positive material identification (PMI), TechCorr offers a comprehensive suite of NDT services to meet your unique inspection requirements.

Safety and Compliance

Safety is our top priority at TechCorr. We adhere to strict safety protocols and regulatory standards to ensure the well-being of our technicians and the integrity of your assets. Our commitment to safety extends to all aspects of our operations, from planning and execution to reporting and documentation.

Efficiency and Flexibility

TechCorr's mobile NDE laboratories provide unparalleled flexibility and efficiency, allowing us to bring our inspection services directly to your project site. This minimizes downtime and disruption to your operations, saving you time and money while ensuring timely and accurate inspection results.

Customer Satisfaction

At TechCorr, we prioritize customer satisfaction above all else. We work closely with our clients to understand their specific needs and objectives, providing tailored solutions that deliver results. Our dedication to excellence and customer service has earned us a reputation as a trusted partner in the industry.

We integrate engineering design excellence with construction

We Serve Assets Nationwide

- Mobile NDE Laboratories

- Expertise in Challenging Environments

TechCorr operates approximately 150 mobile NDE laboratories staffed with experienced technicians certified in accordance with ASNT standards. Equipped with state-of-the-art equipment and personnel proficient in conventional NDE techniques, our mobile labs deliver unparalleled inspection capabilities directly to your project site.

Recognizing the diverse inspection needs of our clients, TechCorr's NDT inspection services encompass a variety of challenging environments. Our rope access teams, certified unmanned system pilots, and trained divers ensure assets in at-height, confined space, and subsea locations are inspected with utmost precision and regularity.

November 6, 2024. 8:08 PM

Short Range Ultrasonic Testing (SRUT) Corrosion Under Pipe Supports

Short Range Ultrasonic Technique (SRUT) was designed mainly to test the Annular Plate of Above Ground Storage Tanks (AST’s) while the tank remains in-service, finding out Corrosion Under Pipe Supports, corrosion at soil air interfaces, and similar difficult to access locations. The technique is based on the

November 6, 2024. 7:30 PM

Short Range Ultrasonic Testing of Critical Zone One In Aboveground Storage Tanks

Short Range Ultrasonic Testing of Critical Zone One In Aboveground Storage Tanks Above Ground Storage Tank (AGST) bottom consists of two separate sections, the central portion (referred to as bottom plate) and also a Sketch Plate or an Annular Plate. The bottom plate is like a membrane

November 6, 2024. 7:04 PM

Short Range Ultrasonic Testing (SRUT)

SRUT examination of the annular ring was conducted at 8 equally spaced locations around the circumference of the tank. Each scan was of 1 m in length around the circumference and extended circa 0.8 m into the tank. In addition to this full scanning of annular plates

November 5, 2024. 2:39 PM

Corrosion under Fireproofing On The Vessel Skirts

ABSTRACT: Corrosion under insulation & fireproofing has become more critical in the industry for a number of reasons. For one, the industry as a whole has become more complex. Chemical, petroleum and food processing facilities to name a few, require more sophisticated equipment, instruments and piping arrangement.

November 4, 2024. 6:40 PM

Pulsed Eddy Current Testing of Subsea Pipline System

INTRODUCTION: Subsea pipelines or submarine pipelines are those usually laydown on seabed or inside of a trench below sea. Due to the marine conditions (sea roughness, alkaline conditions) and the self-contents, pipelines are usually under high risk of corrosion and erosion damage mechanisms apart from mechanical loading

June 11, 2024. 8:56 PM

Ensuring Operational Integrity: TechCorr’s Post-Fire Hardness Test Analysis

We performed a thorough hardness test analysis using cutting-edge...

PARTNER WITH TECHCORR FOR UNRIVALED NDT EXCELLENCE

Learn more about our services and how we can support your Non-Destructive Testing needs.

Subscribe to our Newsletter

We respect your privacy and do not tolerate spam