Optimize Project Timelines & Minimize Operational Disruptions

Infrared Thermography stands as a vital technique in non-destructive testing, providing crucial insights for a wide range of applications. TechCorr leverages this technology for internal and external furnace scanning, electrical scanning (MCC, lighting panels, switchgear), mechanical asset monitoring (bearings, motor cases, rollers), and any temperature-dependent process components (heaters, heat tracing, piping, storage tank levels, refrigeration, distribution racks).

Properly functioning refractory is pivotal to efficient furnace operations and temperature-dependent processes such as cryogenic transport (LNG), distillation, steel processing, and smelting. Non-uniform temperature profiles can induce stresses, drastically reducing asset service life and causing operational hazards.

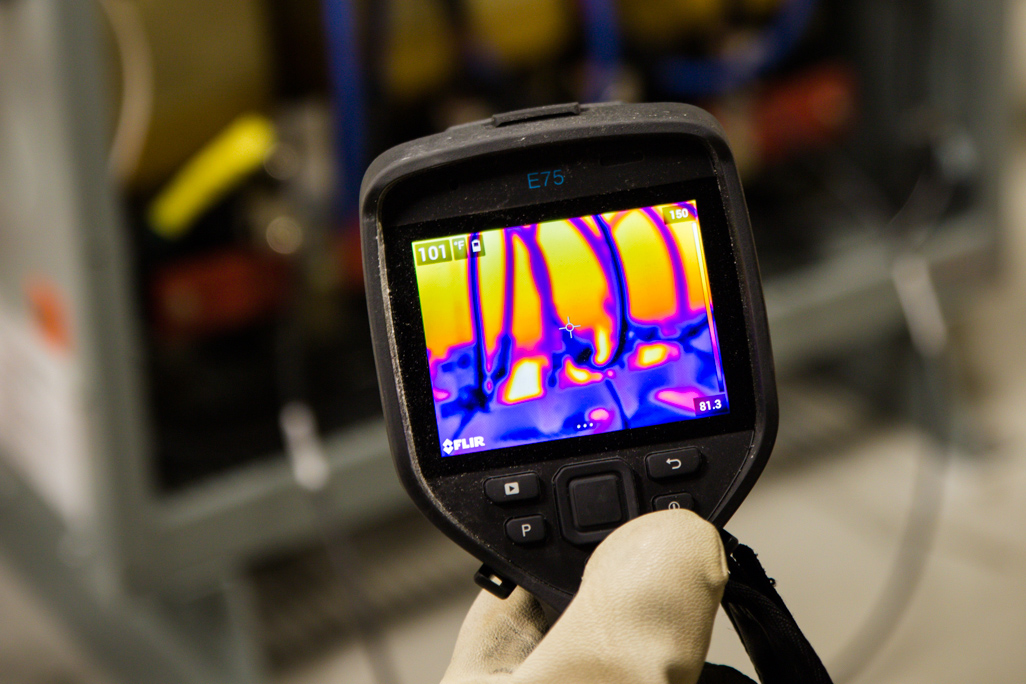

Operations personnel often assume that installed refractory and vessel/piping lining are intact if no exterior damage is visible. However, infrared imaging can reveal hidden issues. TechCorr’s thermography scanning process provides precise infrared images, highlighting potential problems and enabling informed process decisions.

A trained thermographer using a calibrated infrared imager and documented procedures ensures consistent, accurate data collection and interpretation. Infrared Thermography is indispensable for troubleshooting process issues and monitoring refractory degradation over time. Handheld temperature devices can be misleading and are often misused by untrained personnel, underscoring the importance of professional thermography services.