ADVANCED NDE

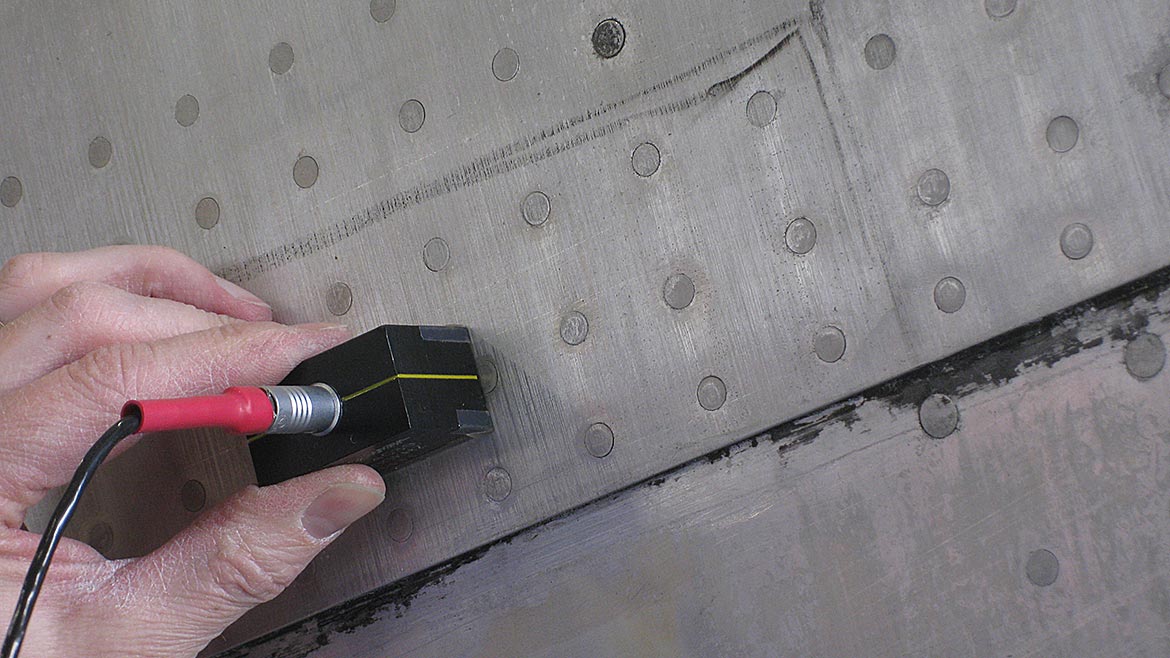

Surface Eddy Current for Stress Corrosion Cracking (SCC)

TechCorr employs advanced Surface Eddy Current (SEC) technology to detect Stress Corrosion Cracking (SCC) in critical components like high-pressure gas pipes, vessels, tanks, and pipelines. SCC, resulting from stress and corrosive environments, poses a significant threat to pipeline integrity.

Traditional non-destructive testing (NDT) methods struggle to detect fine surface-breaking cracks characteristic of SCC colonies. Our SEC screening tool, the Spyne, offers unparalleled productivity and adaptability, accommodating flexible probes for ferritic and non-ferritic alloys. With a detection range from 150 millimeters (6 inches) to flat surfaces, Spyne ensures early detection and assessment of SCC, safeguarding against catastrophic failures.

Traditional non-destructive testing (NDT) methods struggle to detect fine surface-breaking cracks characteristic of SCC colonies. Our SEC screening tool, the Spyne, offers unparalleled productivity and adaptability, accommodating flexible probes for ferritic and non-ferritic alloys. With a detection range from 150 millimeters (6 inches) to flat surfaces, Spyne ensures early detection and assessment of SCC, safeguarding against catastrophic failures.