Optimize Project Timelines & Minimize Operational Disruptions

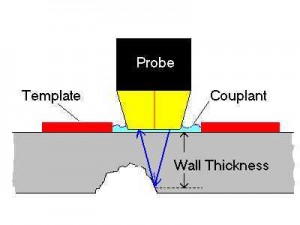

Ultrasonic Thickness Testing (UTT) is a non-destructive method employed to analyze the local thickness of solid materials, relying on the time taken by ultrasound waves to return to the surface. This technique, extensively utilized in industrial settings like mining, offers unparalleled insights into metal thickness and weld quality.

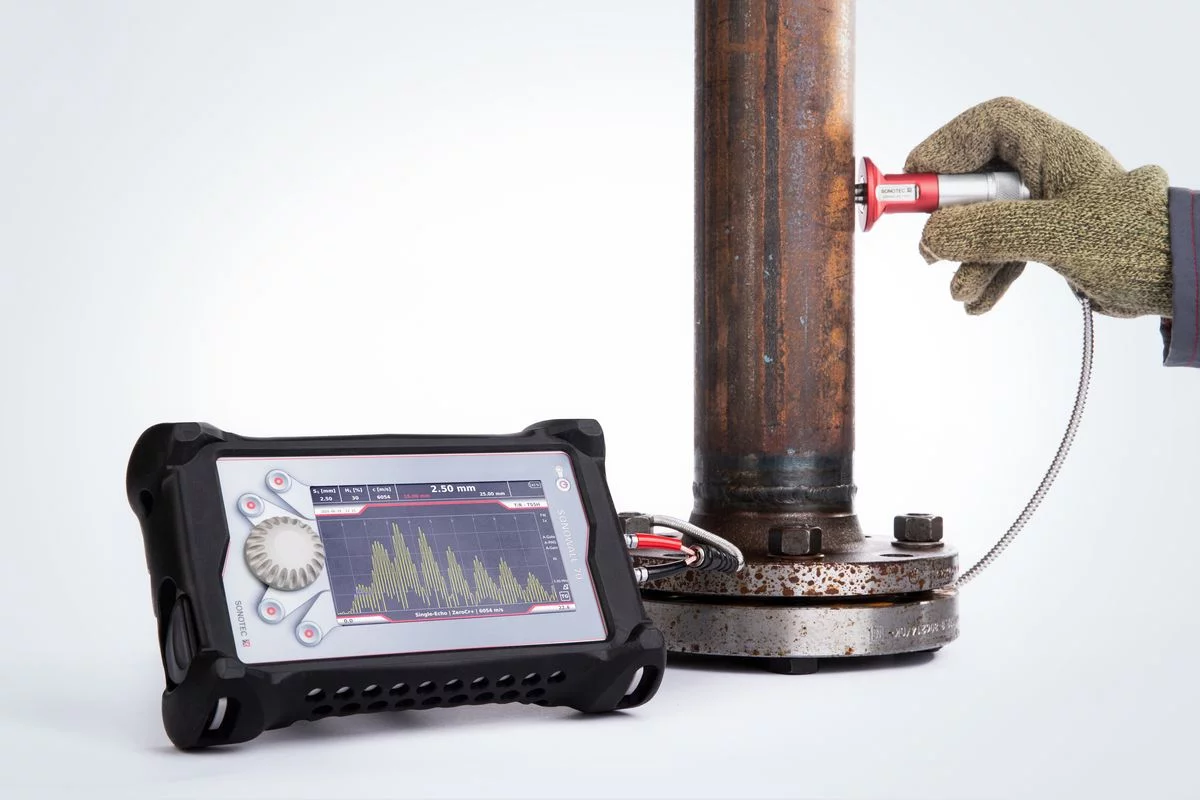

TechCorr's proficient technicians utilize portable Ultrasonic Thickness Measurement (UTM) probes to access steel plating in intricate spaces such as tanks, decks, and superstructures, delivering precise measurements by direct contact with the material. The method's advantages include its ability to operate with coatings and linings, achieving high accuracy levels (up to 0.1 mm) through standard timing techniques, and its ease of deployment without necessitating laboratory conditions. Furthermore, the use of EMAT (Electromagnetic Acoustic Transducer) eliminates the requirement for couplant, facilitating thickness measurements through corrosion and surface coatings on metals without the need for their removal.