EXCHANGER INSPECTION

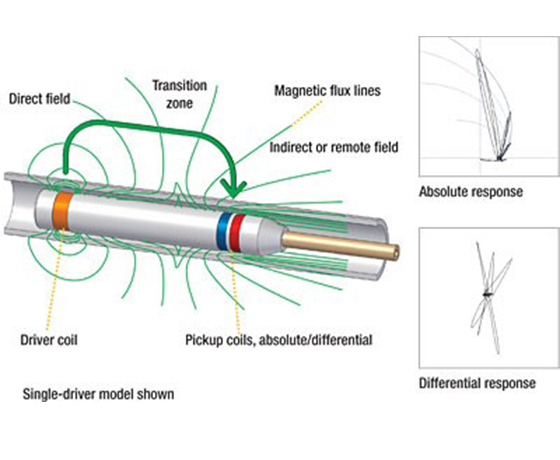

Remote Field Testing (RFT)

Remote Field Testing (RFT) is a specialized non-destructive testing (NDT) technique primarily utilized for inspecting ferromagnetic tubing. Unlike conventional eddy current methods, RFT offers enhanced sensitivity to detect and size discontinuities on both inner and outer tube surfaces, making it ideal for identifying corrosion, erosion, pitting, fretting, and gradual wall loss commonly found in ferromagnetic materials. With its ability to penetrate through the entire thickness of the tube wall and detect variations in wall thickness, RFT ensures comprehensive and accurate inspection results.