Compared to traditional ultrasonic techniques, which require the removal of insulation and specialized probes for accurate measurements, PEC offers significant advantages in terms of efficiency and cost-effectiveness. By eliminating the need for insulation removal, PEC reduces downtime and associated labor costs, making it an ideal solution for routine inspections and maintenance programs.

In summary, Pulsed Eddy Current Inspection (PEC) is a powerful tool for detecting hidden corrosion and assessing the integrity of steel structures in a non-intrusive and cost-effective manner. With TechCorr's expertise in PEC inspection services, clients can confidently mitigate corrosion risks and prolong the lifespan of their assets without disruption to operations.

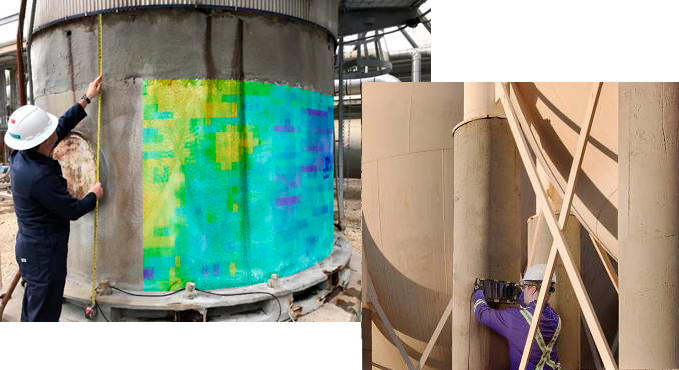

PEC operates by inducing an electric current into a transmitter coil, generating a pulsed magnetic field. This field penetrates through insulation or other surface coatings and interacts with the underlying steel structure. The induced eddy currents in the steel create secondary magnetic fields, which are detected by the receiver coil. By analyzing the amplitude and phase of the received signals, PEC accurately determines the thickness of the steel and identifies areas of corrosion or degradation.

Mathematically, PEC measurements are based on the principles of electromagnetic induction and the interaction between magnetic fields and conductive materials. The strength and distribution of the induced eddy currents are influenced by factors such as the thickness of the steel, the properties of the insulation or coating, and the presence of corrosion or defects.