Find our latest projects

- 713-524-2768

- [email protected]

- 1485 East Sam Houston Pkwy S, Pasadena, TX 77503, USA

UNLOCK A ROBUST OFFERING OF ADVANCED NDT SOLUTIONS

Unparalleled accuracy, reliability, and efficiency in asset management and monitoring.

Our Solutions

TechCorr’s Advanced Group offers a superior level of non-destructive testing (NDT) services, surpassing conventional methods to provide unparalleled insight into asset condition and integrity. Our team utilizes cutting-edge equipment and technology, ensuring swift, precise, and detailed asset integrity data, resulting in a higher probability of flaw detection compared to traditional methods.

Asset Lifecycle Specialist

Conventional & Advanced NDT

Improved Quality and Higher Safety

Mechanical Crafts Support

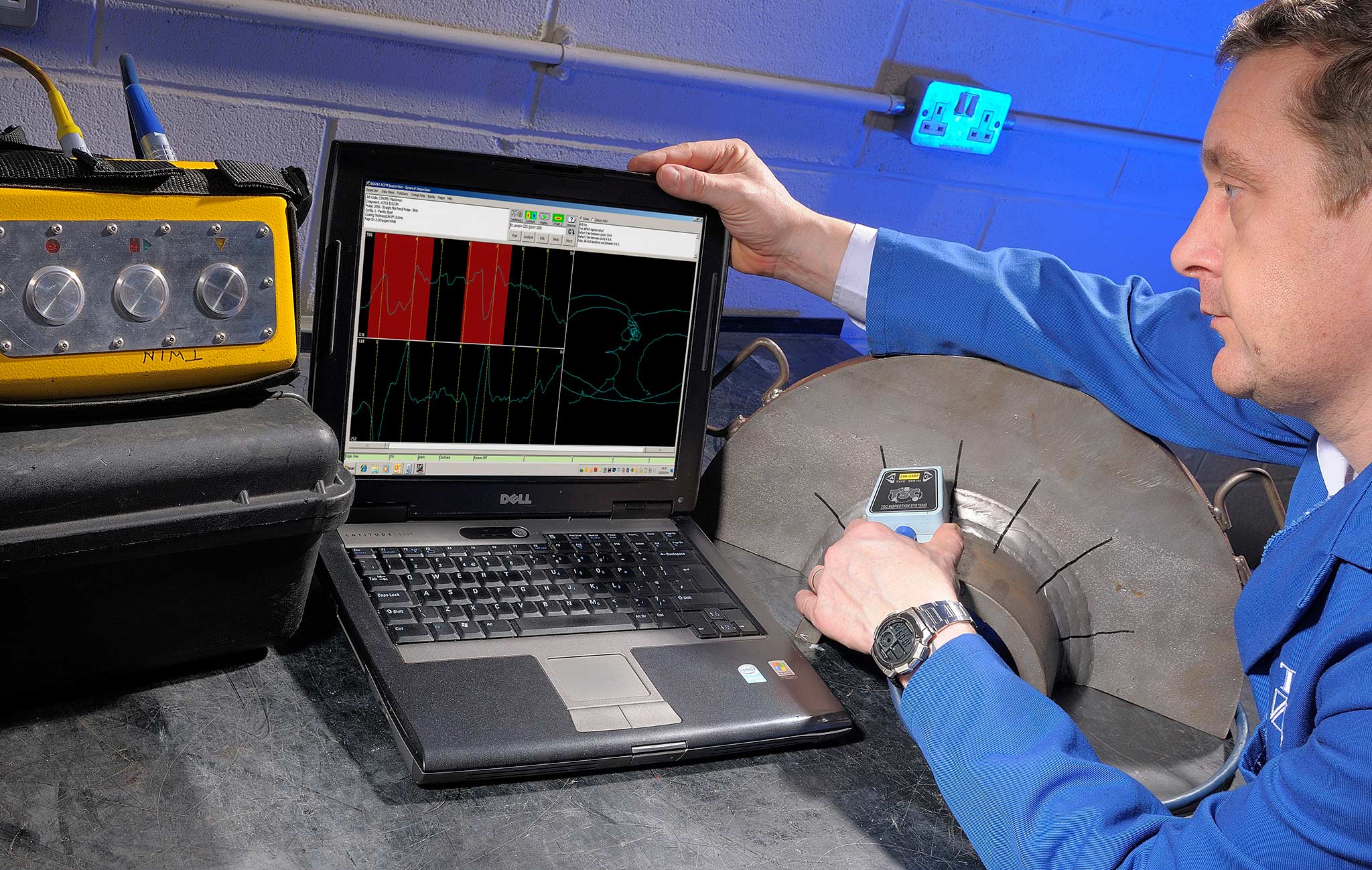

Alternating Current Field Measurement (ACFM)

ACFM is a non-invasive technique designed for detecting surface-breaking flaws in conductive materials. By utilizing alternating currents, it provides accurate measurements of crack depth and location, ensuring the integrity of your assets while minimizing operational downtime.

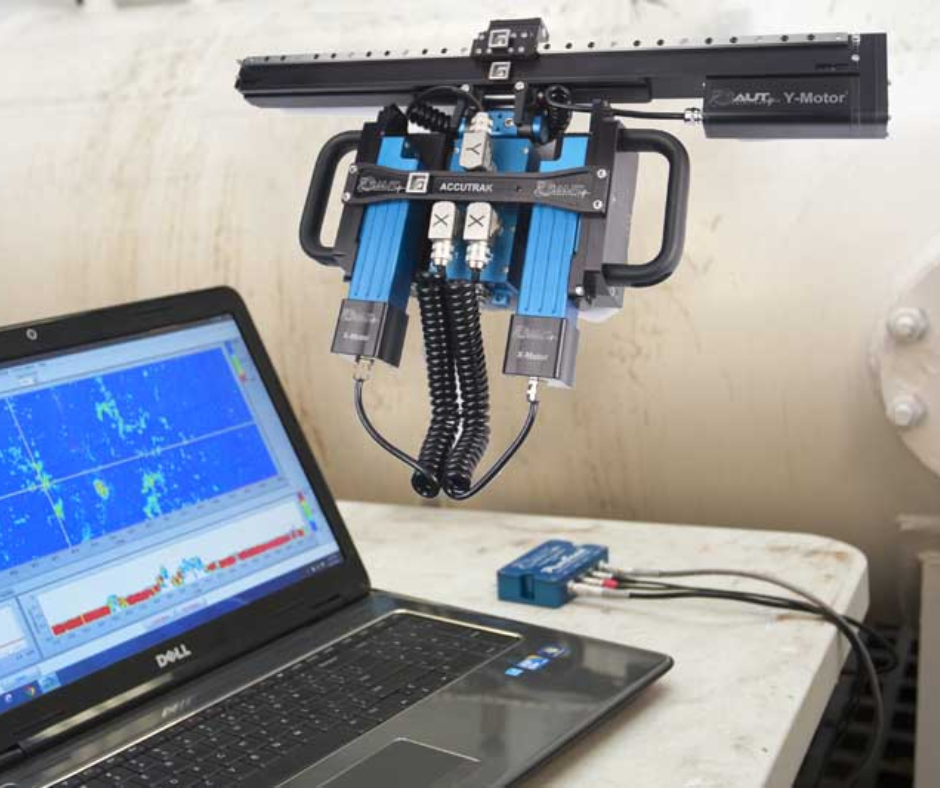

Automated Corrosion Mapping

Automated Corrosion Mapping employs advanced technologies to quickly assess corrosion across large surface areas. This method provides precise measurements and detailed visual data, enabling proactive maintenance planning and enhancing the longevity of your assets.

Creaform Laser Testing

Creaform Laser Testing utilizes state-of-the-art laser scanning technology to deliver high-resolution 3D models of asset surfaces. This non-contact method ensures accurate detection of irregularities, providing valuable insights for effective asset management and maintenance strategies.

Electromagnetic Acoustic Testing (EMAT)

EMAT provides a unique solution for detecting flaws in a wide range of materials without needing couplants. This non-destructive testing method is effective for detecting corrosion and structural anomalies, ensuring the safety and integrity of your assets.

Full Matrix Capture (FMC) & Total Focus Method (TFM)

FMC and TFM are cutting-edge ultrasonic testing techniques that provide high-resolution imaging of subsurface flaws. By capturing data from multiple angles, these methods enhance defect detection and characterization, ensuring thorough inspections and robust asset integrity.

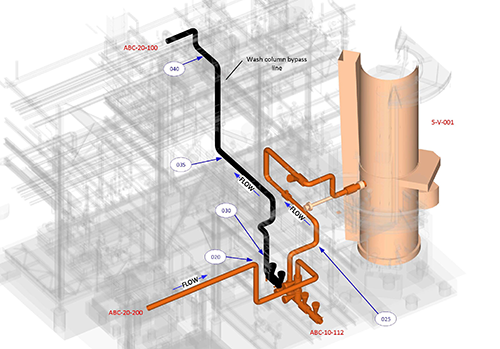

Long Range (LRUT) / Guided Wave (GWUT) Ultrasonic Testing

LRUT and GWUT are effective techniques for inspecting long lengths of pipe with minimal access. These methods detect corrosion and defects over significant distances, allowing for timely maintenance interventions and ensuring the reliability of pipeline systems.

Phased Array Ultrasonic Testing (PAUT)

PAUT utilizes multiple ultrasonic elements to create detailed images of welds and structures. This advanced method enhances defect detection and characterization, providing precise data to support effective asset management and compliance with safety standards.

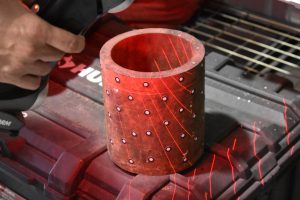

Surface Eddy Current for Stress Corrosion Cracking (SCC)

Surface Eddy Current testing is specifically designed to detect stress corrosion cracking in conductive materials. This sensitive method provides reliable assessments, helping you address potential issues before they escalate and ensuring the safety of your assets.

Time of Flight Diffraction (TOFD)

TOFD is a highly effective ultrasonic technique for detecting and sizing weld defects. By measuring the time it takes for sound waves to travel to and from flaws, TOFD provides precise data essential for maintaining asset integrity and compliance.

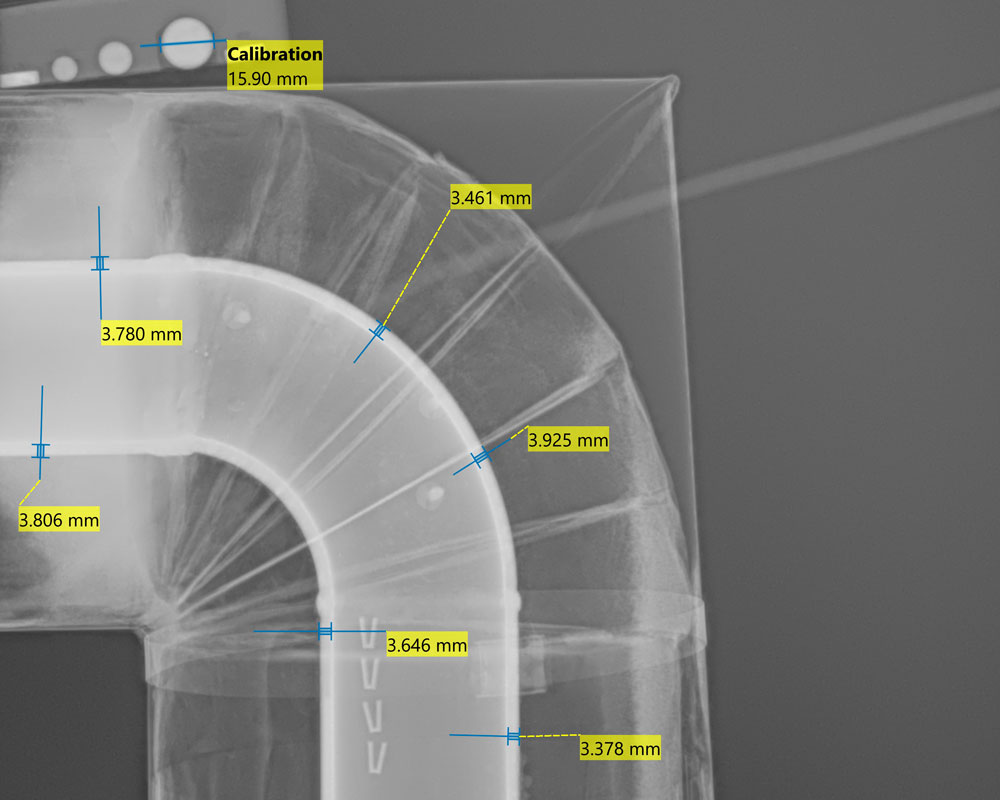

Digital Radiography

Digital Radiography provides clear, high-resolution images of internal structures, allowing for the quick identification of flaws such as weld defects or corrosion. This efficient method reduces exposure times and enhances the accuracy of inspections.

Touch Point Corrosion (TPC)

Touch Point Corrosion (TPC) technology enables precise measurement of localized corrosion on surfaces. By providing detailed data on corrosion rates, TPC assists in making informed maintenance decisions, enhancing the longevity of your assets.

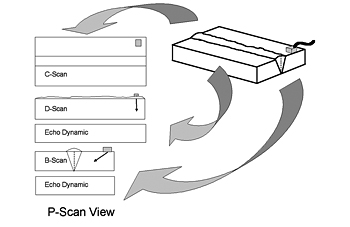

Ultrasonic P-Scan Technology

Ultrasonic P-Scan Technology delivers high-resolution imaging of material integrity by utilizing phased array principles. This method effectively identifies defects and variations in thickness, ensuring robust assessments of critical components.

Pulsed Eddy Current (PEC) Technology

PEC Technology offers an effective way to detect corrosion in non-ferrous materials without requiring tank entry. This non-invasive technique provides rapid and reliable results, ensuring your assets remain safe and operational.

High Temperature Hydrogran Attack (HTHA)

HTHA testing evaluates the susceptibility of materials to hydrogen damage at elevated temperatures. This specialized inspection helps maintain the integrity of assets operating in high-pressure and high-temperature environments, ensuring safety and compliance.

Automated Ultrasonic Testing (AUT)

AUT leverages advanced automation technologies to perform efficient ultrasonic inspections of welds and structures. This method enhances consistency and accuracy, providing reliable data for effective asset management and maintenance.

Acoustic Emission Testing (AET)

Acoustic Emission Testing (AET) is a powerful and proactive non-destructive testing method that detects high-frequency sound waves generated by material stress, cracks, or corrosion. By providing real-time monitoring of structural integrity, AET allows for early detection of potential failures, enhancing safety and reliability while minimizing downtime in critical assets.

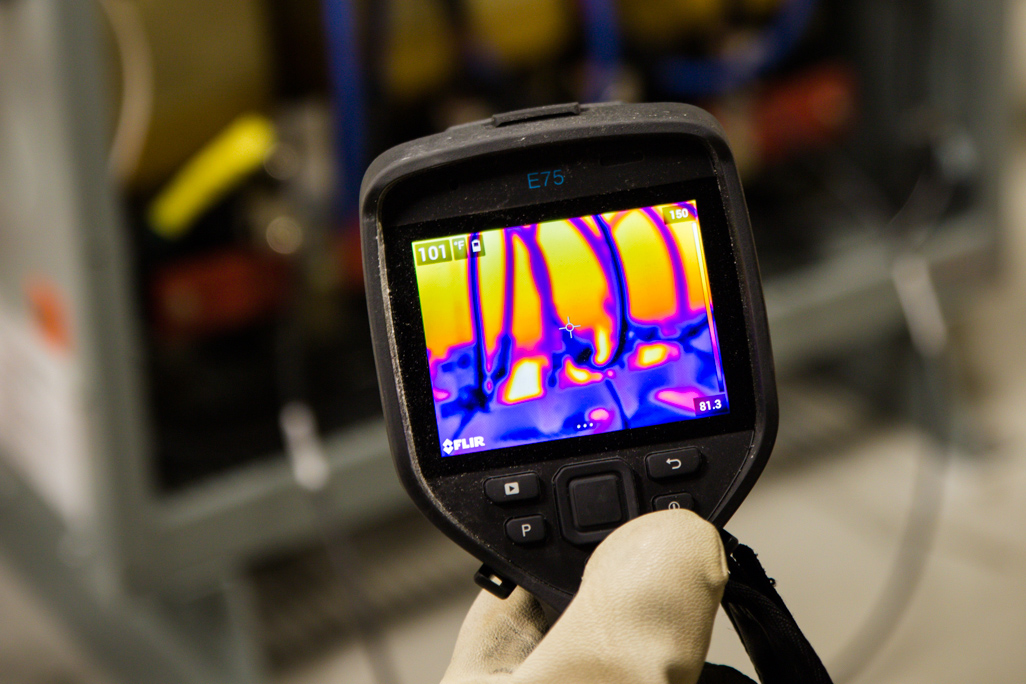

Infrared Thermography Inspection

Infrared Thermography provides a non-contact means to identify thermal anomalies in equipment and systems. By detecting temperature variations, this technique allows for proactive maintenance, helping prevent failures and extend asset life.

Leader in NDT and Asset Integrity Management

Why Choose TechCorr for Advanced NDE

TechCorr is at the forefront of Advanced NDE, utilizing cutting-edge technologies to enhance the accuracy and efficiency of inspections. Our expert team applies innovative methods, such as guided wave ultrasonics and automated systems, to detect and assess flaws that conventional methods may miss, ensuring your assets remain safe and operational.

Comprehensive Services

TechCorr's Advanced Group offers a comprehensive range of ANDT solutions, including but not limited to Advanced Ultrasonic Backscatter Technique (AUBT), Alternating Current Field Measurement (ACFM), Phased Array (PAUT), and Digital Radiography (DR). These techniques are tailored to meet the diverse needs of our clients across industries.

Expanded Insight

With TechCorr's Advanced Group, you gain access to a broader range of inspection methods and technician skills, allowing for enhanced detection and analysis of asset anomalies, including corrosion, cracking, corrosion under insulation (CUI), high-temperature hydrogen attack (HTHA), and weld inspection.

State-of-the-Art Technology

Our advanced NDT solutions employ state-of-the-art equipment and techniques, delivering accurate and comprehensive asset integrity data with unmatched precision and efficiency.

Experienced Technicians

Our team of trained experts possesses extensive experience and expertise in the application and operation of advanced NDT techniques. They are dedicated to delivering superior results and supporting informed decision-making for asset management and maintenance.

We integrate engineering design excellence with construction

Applications of Advanced Techniques

- Common Applications

- Custom Applications

- Custom Design & Monitoring

- Pipeline Inspection

- Tank Assessment

- Vessel Integrity Analysis

- Tower Evaluation

- Fire Damage Assessment

- High Temperature Hydrogen Attack (HTHA)

- Piping Management Program

- Laboratory Services

- Asset Condition Monitoring

- Reliability Engineering

- Remote Monitoring

Other Related Services

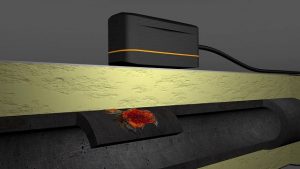

Corrosion Under Pipe Supports (CUPS)

Flange Inspection

Asset Condition Monitoring

Piping Management Program

Fire Damage Assessment

High-Temperature Hydrogen Attack (HTHA)

Laboratory Services

Reliability Engineering

Remote Monitoring

Corrosion Under Pipe Supports (CUPS)

Corrosion Under Pipe Supports (CUPS) is a critical issue that can compromise the integrity of your piping systems. TechCorr’s specialized CUPS inspection services utilize advanced techniques to detect and assess corrosion in these hard-to-reach areas. Our experts provide detailed analysis and actionable insights to prevent failures and extend the life of your assets.

Flange Inspection

Flanges are critical components in any piping system, and their integrity is paramount to system reliability. TechCorr’s flange inspection services employ advanced non-destructive testing methods to identify potential issues such as leaks, cracks, and corrosion. Our thorough inspections ensure the safety and efficiency of your operations.

Asset Condition Monitoring

TechCorr’s Asset Condition Monitoring services provide real-time insights into the health of your critical assets. Using advanced sensors and monitoring technologies, we track key parameters to identify potential issues before they become costly problems. Our solutions help you optimize maintenance schedules and extend asset life.

Piping Management Program

TechCorr’s Piping Management Program offers a comprehensive approach to maintaining the integrity and reliability of your piping systems. Our program includes regular inspections, maintenance planning, and real-time monitoring to ensure your systems operate at peak efficiency. Trust TechCorr to manage your piping assets effectively.

Fire Damage Assessment

In the aftermath of a fire, it’s crucial to assess the extent of damage to your assets. TechCorr’s Fire Damage Assessment services provide a thorough evaluation of affected structures and components. Our experts use advanced techniques to determine the impact and provide recommendations for repair and restoration.

High-Temperature Hydrogen Attack (HTHA)

High-Temperature Hydrogen Attack (HTHA) poses a significant risk to equipment operating under high-pressure hydrogen conditions. TechCorr’s HTHA inspection services utilize advanced non-destructive testing methods to detect early signs of HTHA. Our experts provide detailed analysis and recommendations to mitigate risks.

Laboratory Services

TechCorr’s Laboratory Services offer precise and reliable analysis for a wide range of materials and components. Our state-of-the-art laboratory is equipped with advanced testing equipment to provide accurate results for corrosion analysis, material properties testing, and more. Trust our experts to deliver the insights you need.

Reliability Engineering

TechCorr’s Reliability Engineering services focus on enhancing the performance and dependability of your assets. Our team of experts employs advanced techniques and tools to identify potential failures, optimize maintenance strategies, and improve overall reliability. Achieve operational excellence with our comprehensive solutions.

Remote Monitoring

TechCorr’s Remote Monitoring services provide continuous, real-time oversight of your critical assets from any location. Our advanced monitoring solutions offer instant alerts and detailed analytics, enabling you to make informed decisions quickly. Improve operational efficiency and reduce downtime with our remote monitoring capabilities.

November 6, 2024. 8:08 PM

Short Range Ultrasonic Testing (SRUT) Corrosion Under Pipe Supports

Short Range Ultrasonic Technique (SRUT) was designed mainly to test the Annular Plate of Above Ground Storage Tanks (AST’s) while the tank remains in-service, finding out Corrosion Under Pipe Supports, corrosion at soil air interfaces, and similar difficult to access locations. The technique is based on the

November 6, 2024. 7:30 PM

Short Range Ultrasonic Testing of Critical Zone One In Aboveground Storage Tanks

Short Range Ultrasonic Testing of Critical Zone One In Aboveground Storage Tanks Above Ground Storage Tank (AGST) bottom consists of two separate sections, the central portion (referred to as bottom plate) and also a Sketch Plate or an Annular Plate. The bottom plate is like a membrane

November 6, 2024. 7:04 PM

Short Range Ultrasonic Testing (SRUT)

SRUT examination of the annular ring was conducted at 8 equally spaced locations around the circumference of the tank. Each scan was of 1 m in length around the circumference and extended circa 0.8 m into the tank. In addition to this full scanning of annular plates

November 5, 2024. 2:39 PM

Corrosion under Fireproofing On The Vessel Skirts

ABSTRACT: Corrosion under insulation & fireproofing has become more critical in the industry for a number of reasons. For one, the industry as a whole has become more complex. Chemical, petroleum and food processing facilities to name a few, require more sophisticated equipment, instruments and piping arrangement.

November 4, 2024. 6:40 PM

Pulsed Eddy Current Testing of Subsea Pipline System

INTRODUCTION: Subsea pipelines or submarine pipelines are those usually laydown on seabed or inside of a trench below sea. Due to the marine conditions (sea roughness, alkaline conditions) and the self-contents, pipelines are usually under high risk of corrosion and erosion damage mechanisms apart from mechanical loading

June 11, 2024. 8:56 PM

Ensuring Operational Integrity: TechCorr’s Post-Fire Hardness Test Analysis

We performed a thorough hardness test analysis using cutting-edge...

PARTNER WITH TECHCORR FOR UNRIVALED NDT EXCELLENCE

Learn more about our services and how we can support your Non-Destructive Testing needs.

Subscribe to our Newsletter

We respect your privacy and do not tolerate spam