Find our latest news updates

- 713-524-2768

- [email protected]

- 1485 East Sam Houston Pkwy S, Pasadena, TX 77503, USA

YOUR PIPELINE INTEGRITY PARTNER OF CHOICE

With our expertise, comprehensive solutions, and commitment to excellence, we are your trusted partner for all your pipeline integrity needs

Our Solutions

TechCorr’s Pipeline Integrity group is dedicated to ensuring the reliability and safety of your pipelines through comprehensive inspection and validation services. Our team of experts specializes in non-destructive examination (NDE) of pipelines during anomaly digs and validation of in-line inspection data, utilizing a blend of conventional and advanced technologies to deliver accurate and reliable results.

Asset Lifecycle Specialist

Conventional & Advanced NDT

Improved Quality and Higher Safety

Mechanical Crafts Support

Guided Wave (GWUT) / Long Range (LRUT) Ultrasonic Testing

GWUT/LRUT offers a fast, cost-effective way to assess pipeline integrity over long distances without excavation. This method detects corrosion, cracks, and wall loss in both accessible and inaccessible areas, ensuring the safety and reliability of your pipelines.

Magnetic Particle Inspection (MPI)

Magnetic Particle Inspection is a trusted method for identifying surface and near-surface defects in ferromagnetic materials. It provides fast, accurate results for detecting cracks, seams, and other discontinuities, ensuring the integrity of your critical components.

Creaform Laser Testing

Creaform Laser Testing delivers highly accurate 3D scanning and analysis for asset inspections. Ideal for detecting wear, corrosion, and dimensional changes, this cutting-edge technology provides detailed, real-time data for effective maintenance and repair planning.

Persons In Charge (PIC)

TechCorr’s PICs are highly trained professionals who oversee inspection and testing operations, ensuring that all safety protocols, industry standards, and project goals are met with precision and efficiency.

Leader in NDT and Asset Integrity Management

Why Choose TechCorr for Pipeline Integrity

With extensive experience in pipeline integrity management, TechCorr utilizes advanced inspection technologies to monitor, detect, and mitigate potential pipeline failures. Our thorough evaluations keep your pipelines safe, operational, and compliant, minimizing environmental risks and downtime.

Full Range Expertise

TechCorr's pipeline integrity professionals are highly trained in-house mechanical engineers and technicians experienced in non-destructive examination and anomaly validation. With a deep understanding of industry standards and regulations, we deliver reliable results that meet the highest quality standards.

Comprehensive Solutions

From NDE inspections to soil assessments and engineering support, TechCorr offers a comprehensive range of services to address all aspects of pipeline integrity. Our integrated approach ensures that your pipelines are thoroughly evaluated and maintained to prevent failures and ensure regulatory compliance.

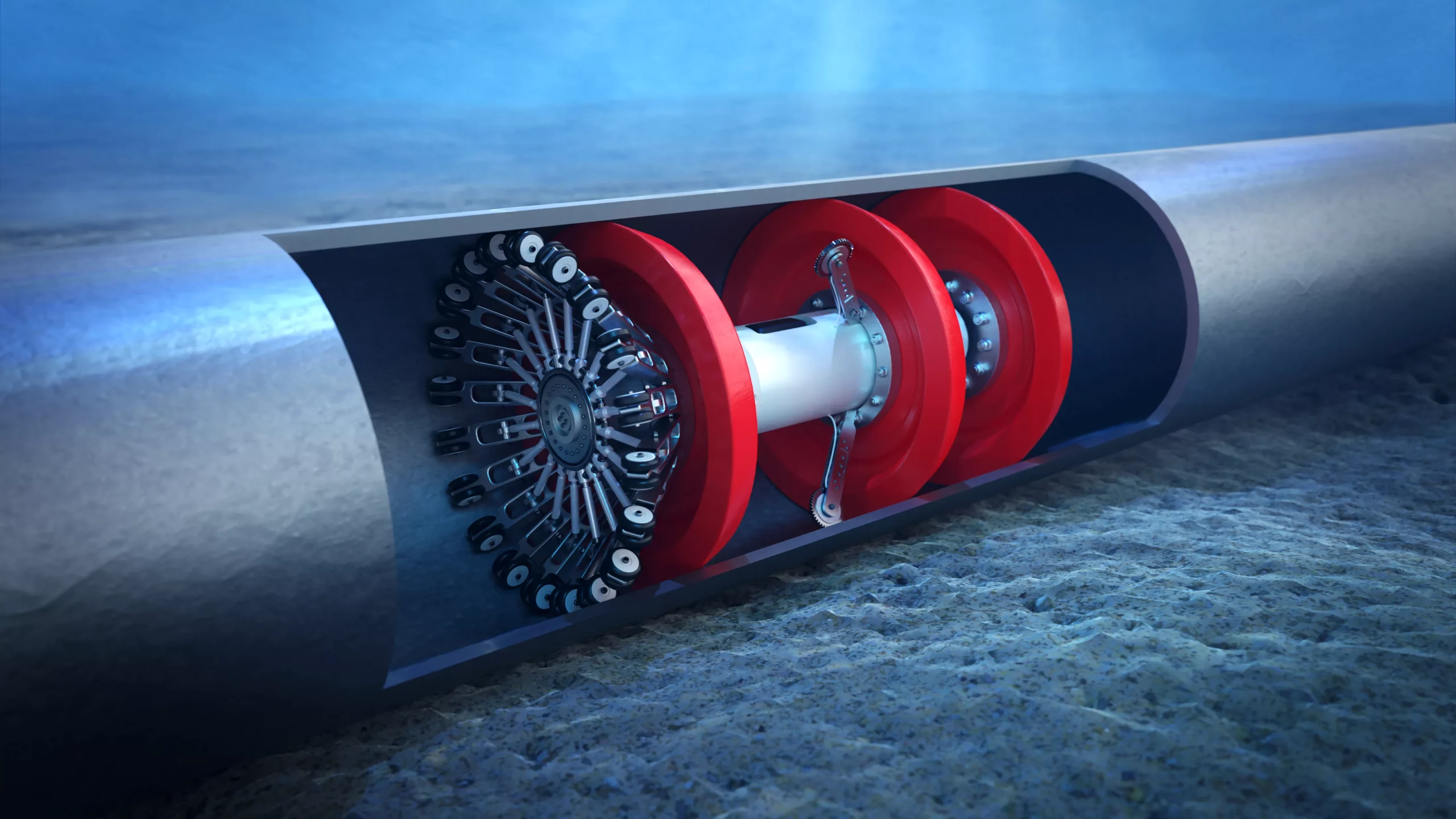

Advanced Technology

We utilize the latest in robotic and sensor technologies and inspection methodologies to provide accurate and efficient assessments of pipeline integrity. By staying at the forefront of technological advancements, we deliver results that are both reliable and cost-effective.

Dedicated Support Team

At TechCorr, we prioritize client satisfaction and strive to provide exceptional service at every step of the process. Our dedicated team of professionals is always available to address your concerns and provide timely updates on project progress.

Our Safety Commitment

Safety is our top priority in everything we do. We adhere to strict safety protocols and procedures to ensure the well-being of our team members and clients. You can trust TechCorr to prioritize safety in all aspects of our work.

Our Safety Commitment

Safety is our top priority in everything we do. We adhere to strict safety protocols and procedures to ensure the well-being of our team members and clients. You can trust TechCorr to prioritize safety in all aspects of our work.

We integrate engineering design excellence with construction

An All-Inclusive Service

- Expert NDE

- Dedicated PICs

- Comprehensive Soil Assessment

- Engineering Support

TechCorr's Pipeline Integrity professionals are equipped with the latest tools and techniques to conduct thorough NDE of pipelines, identifying anomalies and validating inspection data to ensure the integrity of your assets.

We offer experienced PICs who oversee projects and act as the client's representative, providing vital oversight of construction contractor performance and ensuring compliance with project requirements.

Our team is proficient in obtaining soil samples, measuring pipe-to-soil potentials, and assessing soil resistivity, providing valuable insights into corrosion risks and facilitating effective corrosion management strategies.

Backed by a team of skilled engineers, our pipeline integrity professionals can perform detailed engineering analyses, including evaluations of MAOP and Burst Pressures using advanced calculation methodologies.

Pipeline Integrity

Discover the full-range of

Pipeline Integrity related services.

Pipeline Integrity related services.

Other Related Services

ILI (Inline Inspection) Validation

Immediate Emergency Repair

Advanced Services

Repair Inspection & Documentation

ILI (Inline Inspection) Validation

Ensuring accurate pipeline assessments through expert validation of ILI tool data, keeping your pipelines compliant and safe.

Immediate Emergency Repair

Swift and effective pipeline repairs for unexpected damage, minimizing downtime and restoring operational integrity.

Advanced Services

Cutting-edge pipeline inspection using Creaform, Phased Array, and manual mapping to detect critical external and internal anomalies.

Repair Inspection & Documentation

Thorough inspection and documentation of pipeline repairs, ensuring regulatory compliance and long-term operational safety.

November 6, 2024. 8:08 PM

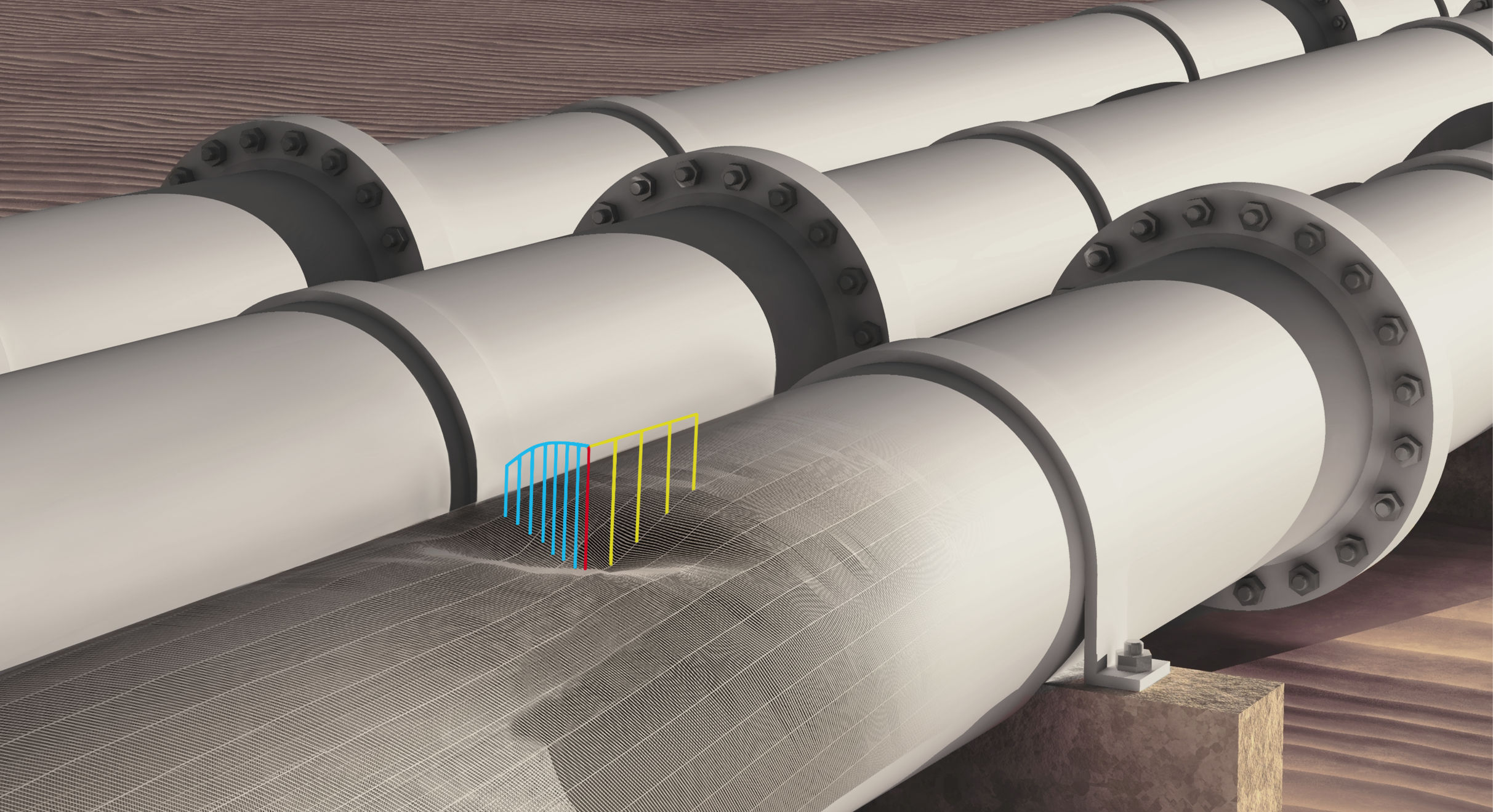

Short Range Ultrasonic Testing (SRUT) Corrosion Under Pipe Supports

Short Range Ultrasonic Technique (SRUT) was designed mainly to test the Annular Plate of Above Ground Storage Tanks (AST’s) while the tank remains in-service, finding out Corrosion Under Pipe Supports, corrosion at soil air interfaces, and similar difficult to access locations. The technique is based on the

November 6, 2024. 7:30 PM

Short Range Ultrasonic Testing of Critical Zone One In Aboveground Storage Tanks

Short Range Ultrasonic Testing of Critical Zone One In Aboveground Storage Tanks Above Ground Storage Tank (AGST) bottom consists of two separate sections, the central portion (referred to as bottom plate) and also a Sketch Plate or an Annular Plate. The bottom plate is like a membrane

November 6, 2024. 7:04 PM

Short Range Ultrasonic Testing (SRUT)

SRUT examination of the annular ring was conducted at 8 equally spaced locations around the circumference of the tank. Each scan was of 1 m in length around the circumference and extended circa 0.8 m into the tank. In addition to this full scanning of annular plates

November 5, 2024. 2:39 PM

Corrosion under Fireproofing On The Vessel Skirts

ABSTRACT: Corrosion under insulation & fireproofing has become more critical in the industry for a number of reasons. For one, the industry as a whole has become more complex. Chemical, petroleum and food processing facilities to name a few, require more sophisticated equipment, instruments and piping arrangement.

November 4, 2024. 6:40 PM

Pulsed Eddy Current Testing of Subsea Pipline System

INTRODUCTION: Subsea pipelines or submarine pipelines are those usually laydown on seabed or inside of a trench below sea. Due to the marine conditions (sea roughness, alkaline conditions) and the self-contents, pipelines are usually under high risk of corrosion and erosion damage mechanisms apart from mechanical loading

June 11, 2024. 8:56 PM

Ensuring Operational Integrity: TechCorr’s Post-Fire Hardness Test Analysis

We performed a thorough hardness test analysis using cutting-edge...

PARTNER WITH TECHCORR FOR UNRIVALED NDT EXCELLENCE

Learn more about our services and how we can support your Pipeline Integrity needs.

Subscribe to our Newsletter

We respect your privacy and do not tolerate spam